Investing in a new welder for a body shop is the equivalent of a lumberjack buying a new axe, or a runner buying a new pair of tennis shoes. It’s one of the most important investments you’ll make, as you’ll likely have no desire to replace it or return it down the road, for a day without your welder, means a day without business. Avoid losing money and valuable time by selecting the right welder for all of your needs in the first place. But, where to begin?

It’s easy to claim that you won’t want to buy the wrong piece of machinery, no one does. But it’s another thing entirely to find the right one for you. As with any large purchase though, you’ll be able to narrow it down with a few key factors, and we have a selection of those that we recommend specifically to help make your decision a bit easier.

What Type Of Welder Do You Need

As you likely know, there are two types of shop welding: You can use metal inert gas (MIG) or tungsten inert gas (TIG). In general, MIG is used far more often in most body shops, unless you’re repairing something like a motorcycle or completing a special repair. That being said, if any one of these is optional, it’s likely the TIG model. Indeed, a body shop cannot survive and perform their primary functions without a high-end MIG welder in its arsenal.

Determine The Extent of the Needed Functionality

One of the main determinations you’ll need to make is whether or not your shop will be doing structural repairs. If you do want to expand your services to include that, or you need to satisfy the services you already offer, you’ll need to invest in a welder that is equipped with a 3-phase inverter resistance spot function. This is because you’ll need the versatility to tackle multiple different types of steel and the different combinations those layers of steel are stacked in. There’s an ever-increasing variance in the car body market for the different types of steels being used and what combination they’re being used in. However, that’s not to say that there are no longer applications for single-phase welders. What your shop does translates to what your shop needs. Ensuring you have a welder on-hand that can handle your project best is the most important step to correctly outfitting your body shop with the right tools.

Power Efficiency

When determining your expectations for the power efficiency of the welder, you’ll also have to consider what type of vehicle you’ll mainly be working on. If you’re considering allowing aluminum body cars into the shop, you’ll have to adjust your expectations accordingly. If you’re wanting to accommodate different types of steel on different car bodies (which we recommend), you’ll need to consider that in your calculations, too. Essentially, the power efficiency of your welder is what you should consider last. If you’re worried about the shop's electric bill, try some LED lights and other power-saving appliances to make-up for the room you can’t make for your welder.

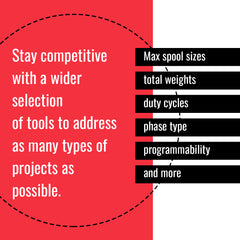

Ensure Versatility

If you’re purchasing a high-end brand like a CHIEF welder, you won’t have to worry so much about quality assurance on the piece as you will have to concern yourself with how versatile the welder is. You’ll want one that can open up your shop to as many services as possible and give your techs opportunities to advance in their field. Consider factors like portability, and how important that is for your business, as well as the size of the components you’re using with the welder.

Ensure that the welder you invest in can toggle up and down based on various factors like the material you’re welding and the thickness of that material to accommodate multiple types of projects. If you can, invest in a smart welder, as it’ll leave more options for upgrades and software enhancements in the future, plus they can often be personalized based on your shop’s specific needs, or your project’s specific needs. Plus, upgradeable software and welders overall have certain longevity to them in the marketplace. Materials in the car construction and body shop businesses are always advancing, if your welder can adapt as time goes on, you won’t have to replace it quite so soon.

Open Up To Possibility

We’ve touched on this before, but your shop should be able to address as many types of body issues as it can, as that means you’ll be turning fewer potential customers away. That means staying up-to-date with the newest types of materials being used and more. It’s widely known that Europe is always adapting their welding technology, which means in order to service European cars correctly, you’ll need a welder that can hang with their standards. After all, when they do, other companies will follow suit. For example, a 3-phase is needed for European cars, and as a result, Ford, Toyota, and other brands are following their lead and making the change as well. What the European market anticipates, you should anticipate as well.

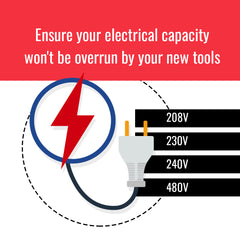

Make Sure Your Wiring Can Handle It

Welders are powerful machines. They require quite a bit of power to operate correctly and not experience any dips in output. That’s not an easy thing to accomplish with just the average electrical set-up. If you’re thinking of investing in the latest and greatest technology for welding, you’ll need to hire an electrician to come and take a look at the shop and ensure that a heavy electrical pull won’t leave the surrounding neighborhood without electricity for the afternoon. Be sure that what you’re investing in can be easily handled by the shop, and equip it to handle it if it’s not already there yet. It’s crucial to stay up-to-date on your tools, but it’s just as crucial to make sure they’ll actually work for you too.

Chassis Liner Supply Selection

All of our CHIEF welders are cutting-edge and can provide you with the variety of functionality you need to complete your project. Making the determination between temperature of welding, weight of the welder and portability, are more of a personal selection process, rather than an industry-need selection process. Largely, it’ll depend on how much electrical power your current wiring can devote to a welder and if you’ll need supplementary welders to accomplish all you need for each type of project you want to address.

For example, our CHIEF MULTIMIG 511, 522, and 621 can all sufficiently weld, upgrade and complete projects at varying speeds. However, you’ll need a spot welder in your arsenal to handle other types of jobs. Anticipating these needs is something only you, who’s in the shop every day, can assess.

Here’s a few of the key differences that should help you select the best type of CHIEF welder for your shop needs.

The 522 model is differentiated from the others by its wire spool size, protection class IP and high-end supply fuse rating. The 621 is programmable and adjustable, making it one of the more versatile main models available. The 511, is above all, easy to handle and control. It’s portable, good for detail work, and a lower weight than the other models listed. Based on the above recommended criteria, you should be able to make industry and personalized decisions easily.

Further Questions About Body Shop Equipment? Reach Out To Chassis Liner Supply Now

If you’re still unsure about what welder is right for you, we can help. We have a knowledgeable staff on-hand who can help you explore the aforementioned pros and cons you’ll need to weigh out before making one of your shop’s most important purchases. Please feel free to reach out with questions about our products today to find out more about how to find the perfect fit for your body shop.

Other Available Car Body Shop Tools

Need something else for your body shop? We provide a wide selection of the absolute essentials for your shop, including paint booth equipment, computer measurement systems for collision repair, and frame racks and accessories. Find everything you need to upgrade and outfit your shop with the proper arsenal of tools to help you expand your capacity and your profits now.